|

Ningbo Angricht Auto Parts Co.,Ltd.

|

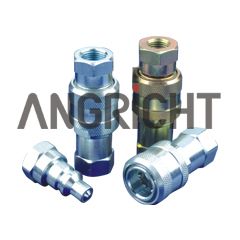

hydraulic quick connection

| Payment Terms: | T/T,L/C |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Hydraulic Quick Coupler

hydraulic flat face couplings

Technical Data:

Manufacturing Standard: ISO16028

Material: carbonized steel(yellow zinc plated)

Seat Design: awl value, steel ball locked

Seal Standard: NBR provided, VITON, etc. provided if need be

Working Pressure: 180-350bar

External Screw Thread: BSP, NPT

Size: 1/4" 3/8" 1/2" 3/4" 1" 11/4" 11/2" 2"

Specifications

Manufacturing Standard: ISO16028

Material: carbonized steel(yellow zinc plated)

Seat Design: awl value, steel ball locked

Seal Standard: NBR provided, VITON, etc. provided if need be

Working Pressure: 180-350bar

External Screw Thread: BSP, NPT

Size: 1/4" 3/8" 1/2" 3/4" 1" 11/4" 11/2" 2"

KSP Series: ISO 16028 Flush Face Coupling Interchange

1. Material: Steel

2. Spring: SS304

3. Back-Up Ring: Teflon

4. Seal: Standard Buna-N -25centidegree + 125centidegree

5. Locking Sleeve type: Option & On Requested

6. Finish:Zinc plated with yellow chromate finish

Interchange Standard

Parker FE Safeway S56 Faster2FFI

Aeroquip FD 89 Snap Tite 74 Dnp PLT4

Tomco FE Stucchi FIRG

Features

1. KSP Series couplings provide non-spill connection/disconnection for general purpose applications.

2. Dimensionally interchangable with ISO16028 standard flush face couplings.

3. Wide selection of body sizes,ranging from 1/ 4" to 2" to provide versatility in a variety of applications.

4. Sealed spring cavity prevents dust collection and possible sleeve binding.

5. Heat treated valve sleeve and poppet resist scratches and wear.

6. Crimped valve seal prevents seal washout.

7. Hardened locking collar sleeve resists brinelling,avoids cracking and provides longer life.

8. Large number of locking balls resists brinelling.

9. Concealed lock ring prevents accidental removal.

10. Zinc plate with yellow chromate finish resists corrosion.

11. Positive lock retaining ring will not wash out under high flow conditions.

12. Induction hardened locking surface reduces wear and brinelling.

13. Anti-blowout Nitrile/PTFE bonded nipple seal prevents damage and blow-out when connecting with residual pressure.

Applications

KSP Series couplings were designed for the construction equipment market and are used extensively on skid steer loaders.The non-spill feature eliminates hydraulic spillage and air inclusion when connecting or disconnecting hydraulic attachments.The KSP Series is also ideal for many other applications where hydraulic spillage is a concern and global interchangeability with other manufacturer is important.

Specifications

Dimension | Maximum Working Pressure | S1 | S2 | L | L2 |

1/4" | 35Mpa | 22 | 22 | 96 | 52.5 |

3/8" | 35Mpa | 27 | 27 | 114.5 | 66 |

1/2" | 35Mpa | 27 | 27 | 124 | 71.5 |

3/4" | 30Mpa | 36 | 36 | 138.5 | 84 |

1" | 27Mpa | 46 | 46 | 151 | 87.5 |

1-1/2" | 25Mpa | 65 | 65 | 215 | 134 |

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Quick Connection

Hydraulic Quick Coupling

Hydraulic Quick Coupler

Hydraulic Quick Release Coupling

Hydraulic Quick Connector

Hydraulic Quick Fitting

More>>

.jpg)

.jpg)

.jpg)